Building a Barrel Culvert Kwoiek Creek, BC

Addendum

Updated Sept 2025

Short video of a stone culvert shot by the author in the Fraser Canyon. It shows the defunct barrel arch which is described in this article. Movie © TW Parkin.

Those readers who’ve read other articles written by me may recognize themes of geology or of stone masonry in many of them. I confess. One my life’s careers was 17 years spent as a stonemason. I returned to writing and railroading history in retirement.

This sequence of historic images, all of the same location but by different photographers, has been assembled for the first time.

Thus, while engaged in research in archives of both provinces, I noted a series of old images having to do with masons and their railway works. Naturally I remembered them and was able to assemble this sequence about a particular project.

They are unusual in that with a bit of professional interpretation, you can see how a typical arch or culvert was built in the era before concrete. This sequence of historic images, all of the same location but by different photographers, has been assembled for the first time.

They show how a trestle at Kwoiek Creek (formerly spelled Quoi-eek) was replaced by a culvert and fill which saved maintenance costs over the continual replacement of aging timbers on the original crossing. Today the crossing is 16.9 railway miles east of North Bend, BC, in CPKC’s Thompson Subdivision. Kwoiek is a tributary of the Fraser River, which runs deep in a canyon here, between the Cascade and Coast Mountains.

Within weeks, higher priorities of politics, timelines, and reduced financing required suspension of [Onderdonk’s] ideals.

Back in 1880, general contractor Andrew Onderdonk1 started construction of the CPR on behalf of the Federal Government. His HQ was at Yale, the head of steamboat navigation, right within the canyon. His first blow against the defying landscape was inland; upriver toward the rest of Canada. Initially, high standards and specifications were provided by Engineer-in-Chief Sandford Fleming back in Ottawa. Within weeks, higher priorities of politics, timelines, and reduced financing required suspension of his ideals. In particular, use of timber was promoted as superior to the use of expensive stone masonry. The construction was calculated to be done ‘cheap and cheerful’—get the job done before going broke—in hope of improving things later.

In The Beginning

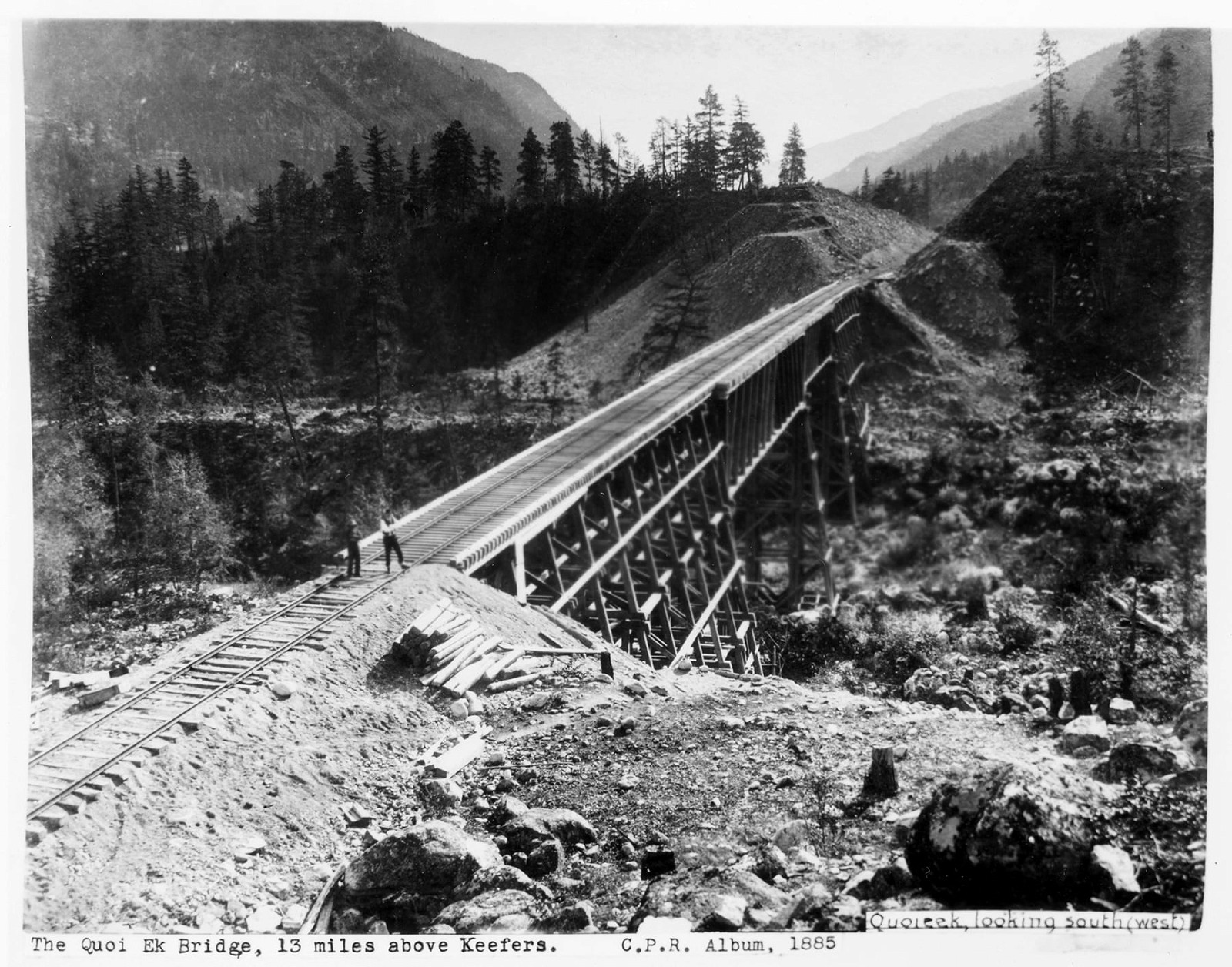

Of particular interest in this scene is the cutting, 16 metres deep, through the opposite bank. It was dug by hand—382,000 m3 of gravel removed! Most of the work is said to have been by Chinese labour. Photo by Charles Macmunn in City of Vancouver Library Special Collections #227. Macmunn typically used one or two figures in his images to denote scale.

When photographed in this 1885 image, Kwoiek trestle was approximately one year old. Its untreated wood would have had a lifespan of 10-12 years. This structure was replaced about age 11 because, after the CPR accepted transfer of ownership on 1 July 1886 from Onderdonk1, it found many instances of inadequate construction. It took several years of legal wrangling before their case was proven, but they didn’t win much compensation.

The central pier can be seen to be built on a ‘mudsill’, merely a foundation of horizontal timbers which simply brace the uprights by gravity.

Although it doesn’t show well in this image, this bridge must have been at risk for flood damage. Howe trusses carry the track high above, but both the bents (vertical assembly units) and the timber piers are not driven into the ground like piles. The central pier can be seen to be built on a ‘mudsill’, merely a foundation of horizontal timbers which simply brace the uprights by gravity. They were vulnerable to water erosion as well as damage caused by stream-tumbled boulders and dislodged trees. As well, this is a semi-arid region. Wildfires (some caused by the railway itself) were a known hazard. Note the bridge deck does not yet have water barrels installed for fire suppression.

As operating profits allowed, the CPR recognized it could pay off bondholders. So with time, it returned to its early ideals. Thereby began a program of over 15 years in duration, where wooden structures were replaced, sometimes with stone and steel, sometimes with huge fills. It was an significant era of transition for civil engineers.

This photographer is unknown and this image was found at the Glenbow Archives, U of C, AB, # NA-1459-6.

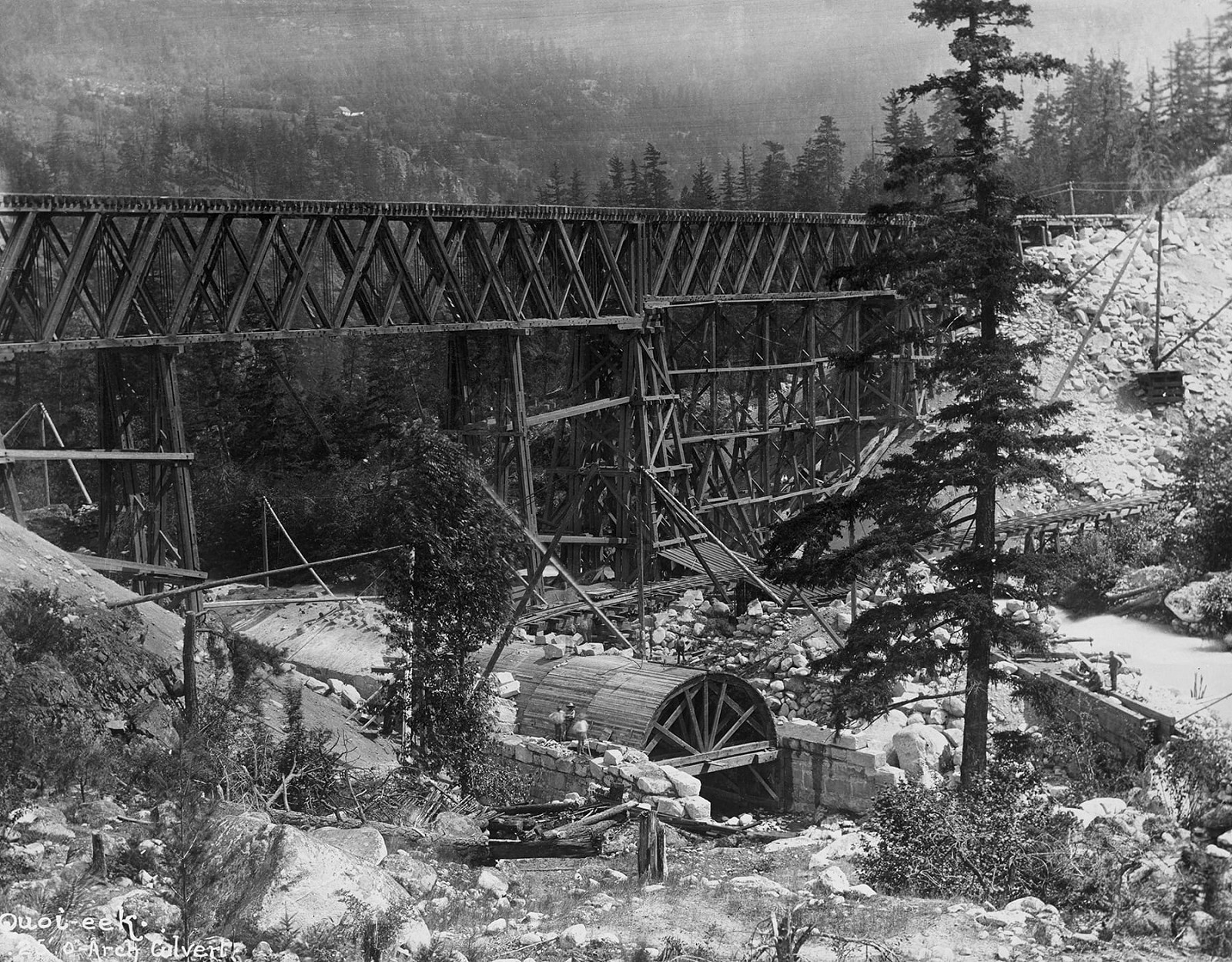

Performing for the camera, this crew of nine has hoisted two fellows aloft and steady their sway with hand lines. The trestle is immediately behind the photographer, so this view is the upstream end of the barrel. The crew has begun to build the lower walls of a culvert over the creek, following what could be a damaging flood. For the project duration, the creek has been temporarily diverted so masons can work without getting wet or chilled.

Performing for the camera, this crew of nine has hoisted two fellows aloft and steady their sway with hand lines.

On the right bank, one wall has been established, with 2-3 basal courses of cut stone established. The uppermost course of ‘springing stones’ (also called voussoirs) launch the first inward angle of the arch to come. When this initial work is complete on both sides, a carpentry crew will build a strong under-support which will then be sheathed with stone.

The natural rock in the streambed cannot be modified for this purpose, having been tumbled smooth by glaciers and subsequent floodwaters. However, look closely on the left bank. There are scattered angular stones brought from a quarry at nearby Camp 16 (also known as Cathmar). My rediscovery of this source is detailed in a CP Tracks story.

Upon This Rock

(Matthew 16:18)

The shape of the elongated culvert is now visible. From the Glenbow Archives, U of C, AB, #NA-1459-53.

The damage I suspected is implied by this image, where the deck trusses have extra bracing that wouldn’t normally be present. It might be the truss has weakened with age, or it could be the trestle’s footings were injured during high water. Either way, the solution is well underway.

Only one layer of stone is needed to create the culvert; physics being such that it becomes incalculably stronger with additional weight being placed onto it.

Six men are visible here (there must be more, now that carpenters have arrived) building a 25-foot barrel culvert. Stone covers much of the formwork already. Stone being dropped from flatcars onto the far slope, is then lifted by derrick and moved onto a handcart pushed on narrow-gauge rails paralleling the trestle footings. From that cart, two other derricks on the nearest slope choose pieces for placement on the supporting ‘buck’, a temporary arch support. Possibly some similar dump/hoist arrangement was earlier in place on this side of the creek as well.

Note the timber deflection wall keeping the creek aside until its masonry channel is complete. A sand pile for making mortar appears beside the handcart track, between the trestle bents, where it was dumped down between the ties of the track above. All operations are hand-powered.

Only one layer of stone is needed to create the culvert; physics being such that it becomes incalculably stronger with additional weight being placed onto it. Many such culverts and arches are still bearing modern train weights in the Fraser Canyon. Even as late as 1985, a CP Rail engineer stated that hundreds of masonry culverts and abutments were still doing duty on the mainline2.

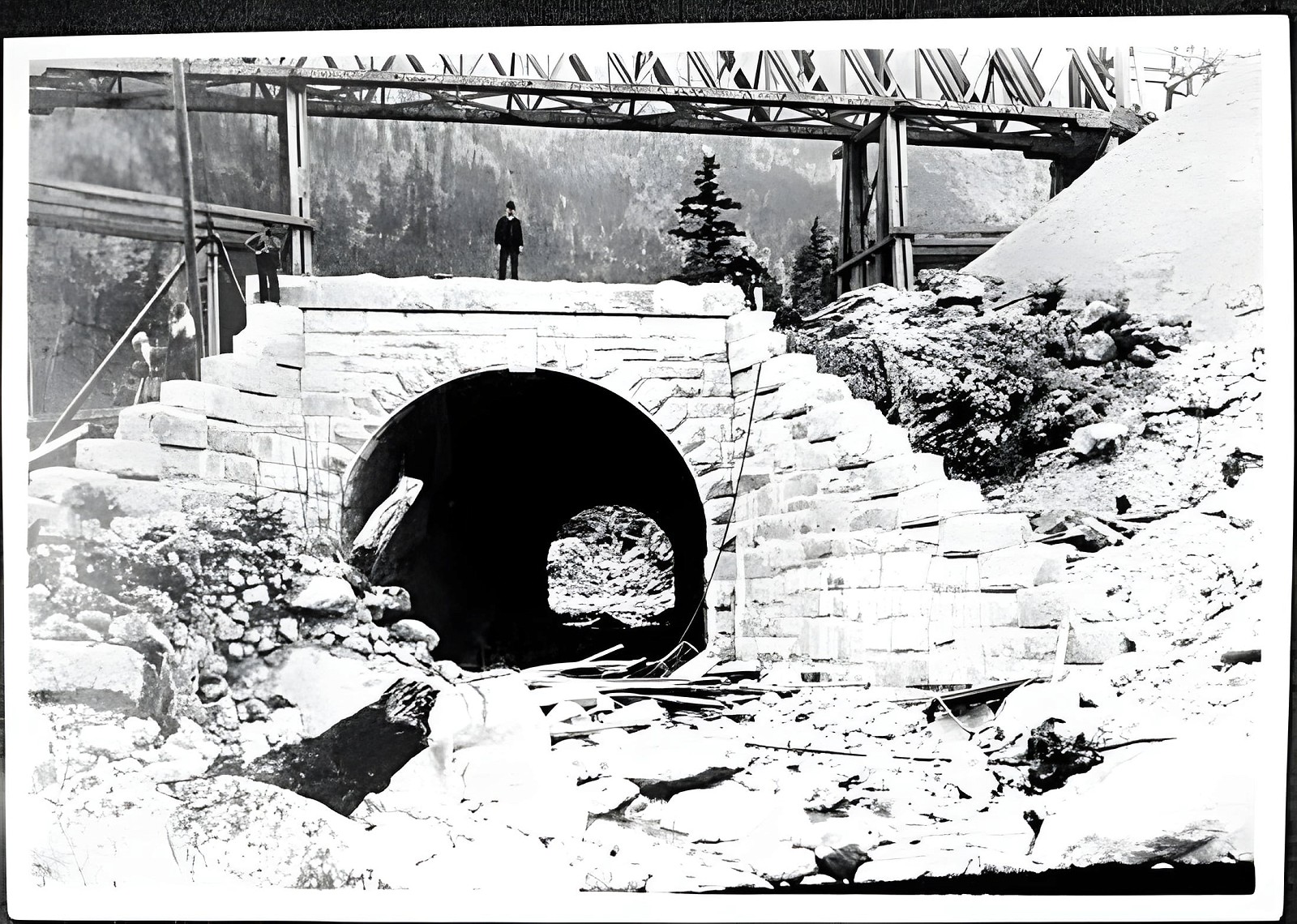

This close view of the culvert inlet shows the tight placement of stones, each laid with its narrowest edge inward. Such wedge shapes provide extra strength to the structure.

A layer of mortar covers adjacent surfaces. When the mortar is fully cured and won’t allow stones to shift, the arch is capable of supporting itself.

See the shims beneath the edges and centre of the buck? Once these are knocked out, the whole of the arch support drops 100 centimetres, so its wood components can then be freely disassembled. The CPR ceased building with stone about 1910/12. After that, concrete became the preferred material.

Near the end, a senior manager shows up to have his photo taken! Some dude in a suit and hat poses like he’s king of the castle with the actual builders being bumped to the perimeter of the image. I doubt he got dirty that day. Photographer unknown, Vancouver Public Library photo #467.

The project is nearly complete: 71 meters long and 7.6 metres wide. The year is 1895. Planks used to support the ceiling are thrown down at the portal, this view being at the downstream end.

...such pride of workmanship was taken on industrial structures never to be seen by the public.

At this stage, the first layer of fill covering the stone would be leftover sand, plus small gravel without large stones which might press directly against the sheath of granite. This material would provide protection from the long drop of heavy rubble cascading from dump cars which will soon bury the trestle. Burial would be done evenly over each haunch of the culvert to distribute stress evenly.

Note the dropped keystone. This is not a necessary positioning, and the effect does not run the length of the roof. It’s done just to emphasize its significance.

For aesthetic effect, in other words—which always amazes me—that such pride of workmanship was taken on industrial structures never to be seen by the public.

The sand and gravel material used here is ideal for the situation. It compacts well and reduces settlement, which in some cases has been measured as high as 10%. Vancouver Public Library photo #366.

Rock, Paper, Scissors

A few years later (17 August 1899, to be exact), the CPR sent out engineer-turned-photographer JW Heckman to document the structure for their files back in Montréal. His wandering steps down the embankment show above the wing wall. The huge effort of this project has increased safety and track speed, thrown carpenters out of work, and greatly reduced the division’s annual maintenance budget.

The huge effort of this project has increased safety and track speed, thrown carpenters out of work, and greatly reduced the division’s annual maintenance budget.

How long the project took is unknown, but notes by supervising engineer HJ Cambie suggest construction started 1893. So two years, overall.

Amazingly, no sign of all this is visible at Kwoiek Creek today. Old CPR subdivision profiles show a steel span of 109 m being present as early as 1934, and it is still in service.

Events are not precisely known, but likely Kwoiek was too quick for the CPR. In some spring flood the culvert may have plugged with debris, which meant the fill would have become a dangerous dam. So then it was back to idea #1, a bridge structure; this time one which allowed free flow of water, and with footings more secure than before.

Conclusion

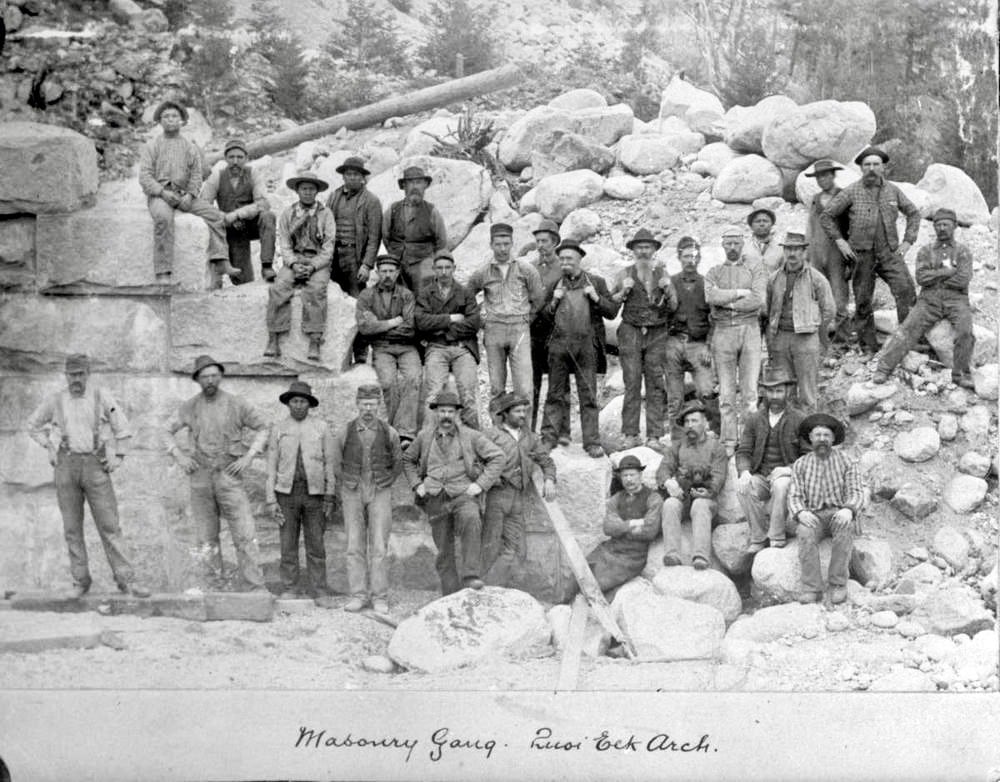

Some years after this story appeared in Branchline magazine, I belatedly discovered this photo of the 28 workmen and one dog who built the Kwoiek project. Unfortunately their names have not been preserved. Some are almost certainly local Nlaka'pamux people.

Thank you, gentlemen; your service of old has not been forgotten.

Endnotes

1 Canada. Department of Railways and Canals. Articles of Agreement Entered into in Connection with the Canadian Pacific Railway, Ottawa, 1880. Onderdonk signed his initial contracts in 1879, but by the time of this printing Fleming had been dismissed due to a new government approach to construction. Nevertheless, in 1884 he was appointed as a director of the CPR and was conspicuous at the driving of its last spike the following year.

2 From ‘The Business Car’, Canadian Rail magazine, issue #384 (Jan/Feb 1985), page 27.

Did You Enjoy This Article?

Sign Up for More!

“The Parkin Lot” is an email newsletter that I publish occasionally for like-minded readers, fellow photographers and writers, amateur historians, publishers, and railfans. If you enjoyed this article, you’ll enjoy The Parkin Lot.

I’d love to have you on board – click below to sign up!